Influence of strength and material on quality of aluminum alloy die casting

Most of the researches on mechanical properties of Custom aluminum casting products are focused on test plates and test rods, but the research on the influence of defects, organization, solid solution and other factors related to product properties is not enough, which leads to many unstable factors in product design. With the increasingly frequent opening to the outside world, the ADC12 aluminum alloy in the JIS standard of Japan has become a main die casting raw material used in domestic common pieces. Therefore, it is necessary to carry out the analysis and research on the material, host and mechanical properties of the ADC12 alloy as the representative material. And aluminum alloy die casting according to the Japanese JIS standard ADC12 aluminum alloy as one of the main raw materials.

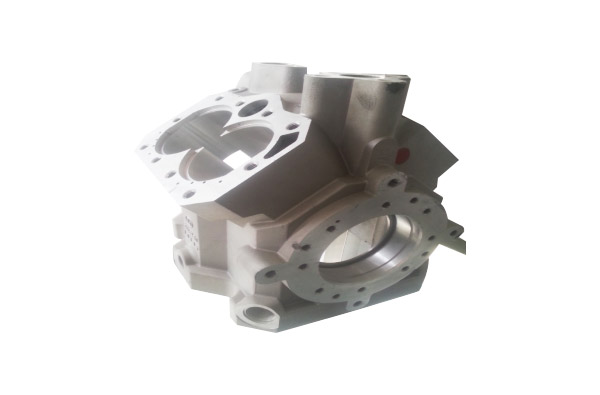

The influence of strength and material on quality of aluminum alloy die casting & High precision aluminum casting is discussed, especially the influence of magnesium, silicon and iron composition on mechanical properties is analyzed. The tensile strength of magnesium remains the same with the increase of magnesium. The tensile strength of copper tends to increase with the addition of copper. Silicon significantly improves fluidity, but silicon is detrimental to machinability. The impact of iron basically increases hardness, decreases elongation and impact toughness.

Changzhou Kadi International Trade Co.,Ltd.

Add. : Room 627, Building 24, Wuyue Square, Hutang Town, Wujin District, Changzhou,Jiangsu,China 213161

Tel : +86 519 8180 9887

Fax : +86 519 8180 9887

E-mail: info@kadi-cn.com jack@kadi-cn.com